Cartridge heater

▇ CTH HEATROD

cartridge heater was developed with premium material and finest craftsmanship since 1987, and it brings you superior heat transfer where it is needed.

▇ Main Features:

- Nickel Chromium resistance wire – Assure even and efficient heat to the sheath long service life.

- Conductor Pin – High Nickel alloy provide stable power transfer and resistance to oxidation and high temperature.

- Magnesium oxide insulation – only premium grade is used to provide maximum dielectric strength and faster heater transfer.

- Incoloy sheath – resists oxidation and corrosion in high temperature and contaminated environment.

- Centerless Grinding – furnish precise diameter, closer heater to bore fit enable higher watt density.

- UL approved wires and insulation – 300V, 600V, 180℃ and 500℃

▇ Sheath Material Options:

|

Material |

Operating Temp. |

|

SUS 304 |

520oC |

|

Incoloy |

760oC |

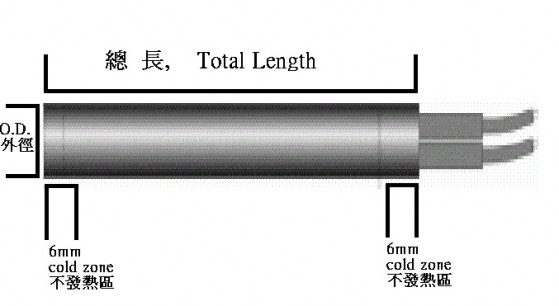

▇ Size Ranges :

|

|

Min. |

Max. |

|

O.D. |

4.75mm |

25.40mm |

|

Length |

23.00mm |

>1500mm |

AC Rating: 110V-480V

DC Rating: 24V-48V

All customized orders are welcome

Even if you do not see your desired spec. here please contact us with any requirements and question you might have.

▇ Lead Wire options:

- Swaged In Leads: Application where lead wire is bent accordingly to fit moulding design, 500℃rated wires are connected internally to prevent failure under high temperature environement.

- Crimped-on Leads: rated 180℃ or 500℃ wires and conductors are joined together by crimp-on process to ensure stable power transfer to the heater.

- Teflon Leads: PFA leads rated 200℃ protects lead wire against moisture and contamination from oil, solvents and fumes. Minimum no heat section 25mm is required.

- Ceramic bead insulation: suited for higher than 500C environment.

- RTV Silicone Sealant(200C) 25mm no-heat section is required

- Epoxy Sealant(220C) 25mm no-heat section is required

- High Temp. Silicone Sealant(350C)

- High Temp. Specialty Cement Sealant(1000C)

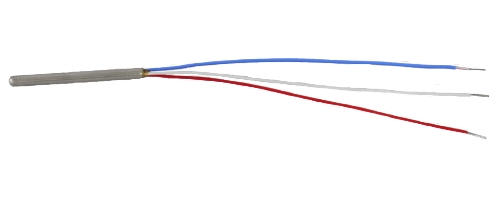

Built-In Thermo-couple Wire

Built-In Thermo-couple Wire K-type or J-type is available

_____________________________________________________

▇ Typical Application:

Injection molding - Internal heating of nozzles

Hot runner systems - Heating of manifolds

Packaging industry - Heating of cutting bars

Vacuumed forming - Heating of manifolds

Laboratories - Heating of critical component

OD tolerance: +0.00mm -0.02mm

Length tolerance: +1.0mm -0.5mm

Output tolerance: +5% -10% (+5%, -5% at request)

QC Standard: 1.5KV/Min Dielectric Test

500V DC Above 100 MegOhm Insulation Test